Introduction:

Industries such as mining, construction, and heavy machinery constantly battle one common issue—abrasion-related wear and tear. Equipment exposed to harsh environments often breaks down prematurely due to surface degradation, leading to frequent replacements, downtime, and skyrocketing maintenance costs. Finding a durable, cost-effective material that can withstand such extreme conditions is a persistent challenge across sectors.

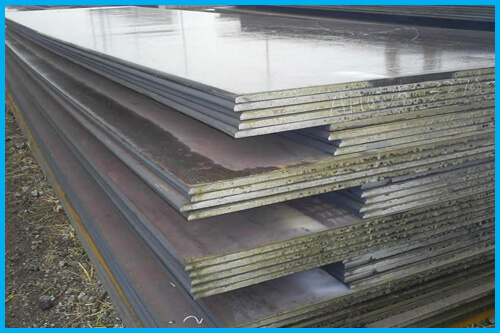

What is Abrex 500 Plate?

Abrex 500 Plate is a high-strength, abrasion-resistant steel plate developed to address these exact concerns. Manufactured with a unique blend of hardness and toughness, Abrex 500 offers a Brinell hardness of approximately 500 HBW, making it ideal for applications that demand both durability and strength. It is particularly suited for high-impact environments where other materials might fail.

Advantages of Abrex 500 Plate

Exceptional Hardness: Designed to withstand intense wear and tear, reducing the frequency of replacements.

High Strength-to-Weight Ratio: Offers robustness without significantly adding weight, improving efficiency and fuel economy in mobile equipment.

Corrosion Resistance: Maintains structural integrity in hostile environments, including exposure to moisture and chemicals.

Cost-Efficient: Reduces long-term operational costs by minimizing maintenance, part replacements, and downtime.

Enhanced Workability: Despite its hardness, it can be cut, welded, and formed with relative ease, offering flexibility in design and fabrication.

Real-Life Uses of Abrex 500 Plate

Mining Industry: Liners for hoppers, chutes, and crushers.

Construction Equipment: Bulldozer blades, excavator buckets, and dump truck bodies.

Cement Industry: Clinker conveyors and mixing blades.

Recycling Plants: Shredders and screens exposed to high impact and friction.

Agriculture: Soil preparation tools and parts that deal with abrasive soil and rocks.

How Abrex 500 Solves the Problem: Outcomes & Impact

Before the introduction of Abrex 500, many industries had to compromise between durability and cost. With this steel plate, businesses experience:

Extended service life of equipment components.

Significantly lower downtime, leading to increased productivity.

Reduced maintenance and part replacement costs over time.

Improved safety, as stronger materials reduce the risk of sudden equipment failure.

By offering unmatched abrasion resistance, Abrex 500 transforms operational efficiency and reliability across multiple industries.

Conclusion

Abrex 500 Plate is not just a material—it’s a performance booster for industries plagued by wear-related challenges. Its introduction has led to tangible improvements in productivity, safety, and cost-effectiveness, making it a go-to solution where durability is non-negotiable.